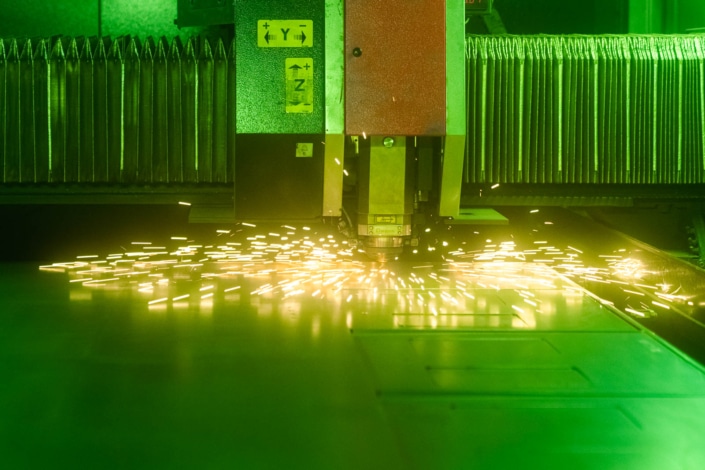

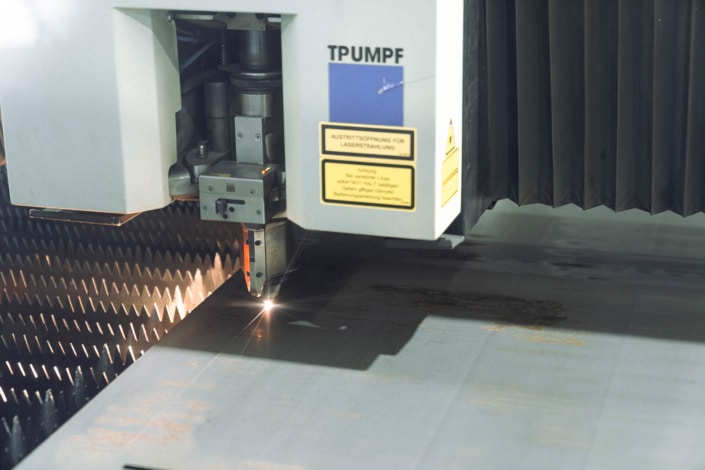

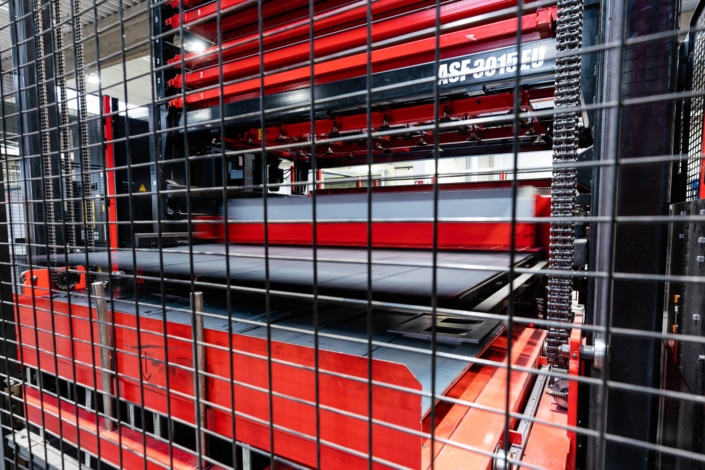

A 6 kW FIBRE laser cutting system with an integrated fully automated tower storage and retrieval system. The storage system automates the loading and unloading process of the laser.

The tower storage system has a modular configuration, giving the user the ability to customize the number of pallets for raw material and for stacking. There are 7 pallets for raw material and 3 stackings for finished parts installed. Each stacking/pallet has a capacity of 3.000 kg, summing up in total to 30.000 kg storage capacity.

Due to the fully automated storage system unmanned production cycles in a nonstop manner ensure high efficiency at low costs.

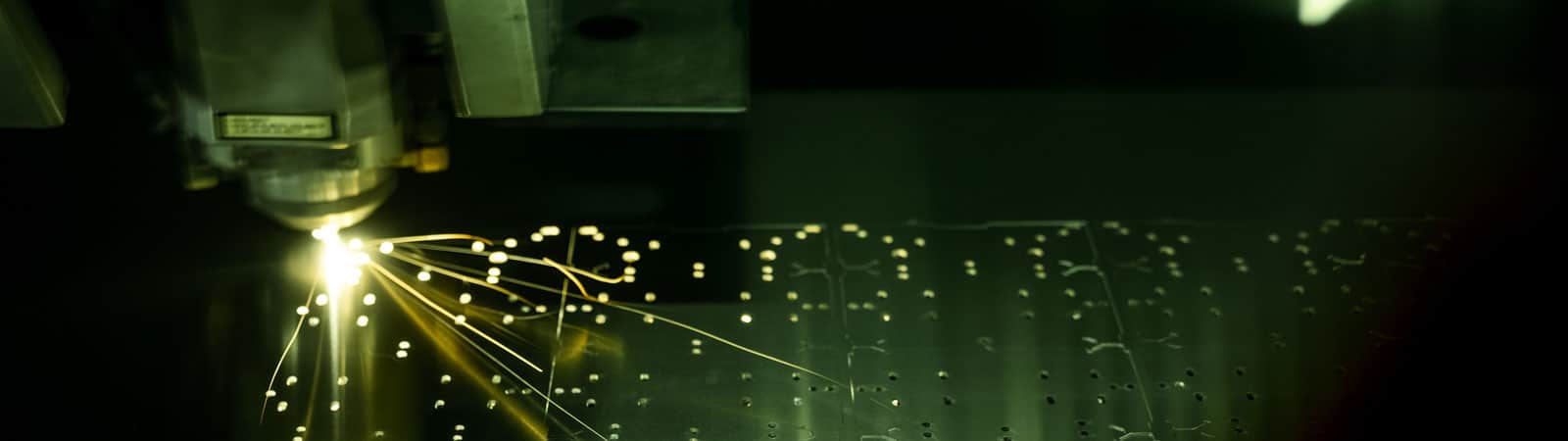

Cross-system programming of the laser cutting system and bending machines ensures efficiency in the production of complicated 3D-parts and highest precision.

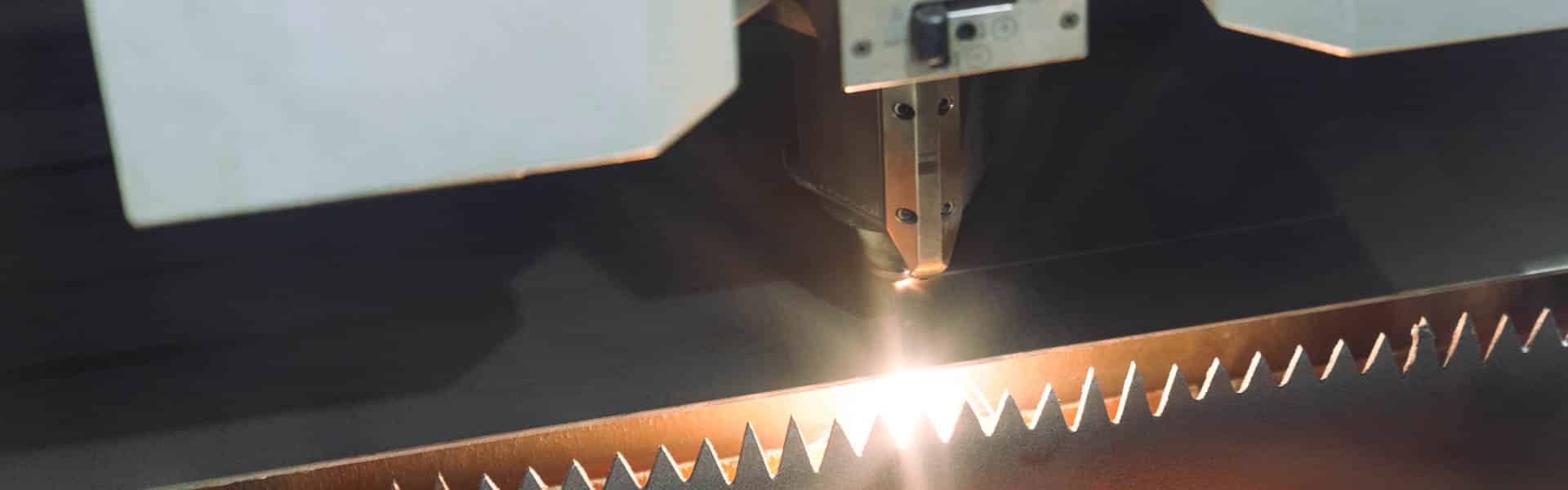

In addition to conventional materials such as plain carbon steel, aluminium alloy and stainless steel the FIBRE-technology is capable for cutting of copper, brass and/or titan.